PM40和PM35透气钢的加工

PORCERAX II-PM35、PM40透气钢的加工可采用常规方法,如铣刀、磨床、研磨抛光、电火花等方法。由于透气钢蜂窝状的气孔结构,加工过程因避免对堵塞进微观孔结构的金属碎屑的去除,因此建议采用冷却油,并在重型表面加工后对表面进行恢复处理(正反面均需要),这一点非常重要!

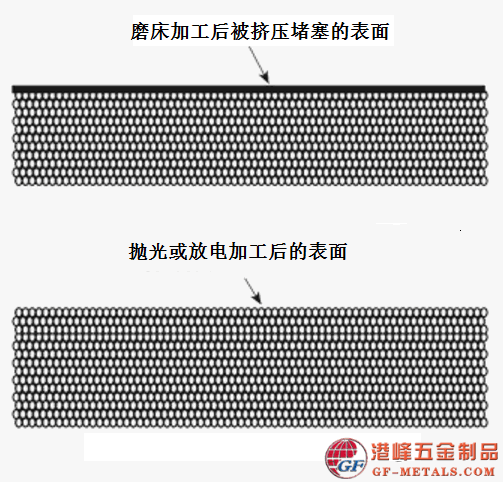

如上图所示,磨削加工堵塞了此透气钢的所有等级气孔毛孔,精铣将导致7微米的孔完全堵塞、20微米的孔径开口下降到7微米。

恢复PM35/PM40透气钢表面孔隙的方法有多重:

1)研磨/抛光

采用800~1000号的砂纸,横向来回+纵向来回研磨,可以清楚被压碎的气孔,重新建立透气钢气体渗透性。在研磨和抛光过程中,不时地冲洗表面,防止碎屑填塞孔非常重要。

2)放电加工

放电加工是恢复PM35/PM40透气钢堵塞面的最佳方式。此方法将烧掉磨削加工中堵塞在孔中的金属碎片。

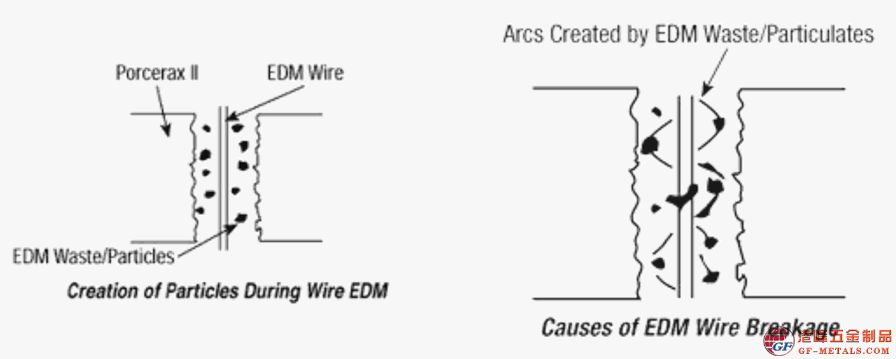

需要注意的是,使用金属线放电加工时,由于PORCERAX II透气钢的孔状结构,空中的微小碎屑可能产生电弧,烧断加工线,解决的办法是提高线速度或者使用较粗的铜线(如0.25mm)。而使用电极放电时,峰值燃烧率因高于透气钢孔隙率,小于7微米的深度加工7微米的孔径是可行的。

上图显示线切割过程中产生的电弧如何携带微粒,增加绕线速度不仅大大降低了断线的可能性也减少了加工时间。

Machining and Polishing

Porcerax II can be machined by conventional methods using cutoff saws, end mills, grinders, EDM methods, stoning, etc. It is important to remember that this material is honey-combed with thousands of microscopic holes which are affected by metal removal. Oil coolant is recommended.

Grinding closes the pores of all grades of this porous steel. Milling will close the pores of 7 micron and reduce the pore size of the 20-micron material down to about 7 microns

(when done correctly) by partially closing the pore opening at the surface. Stoning, using a back and forth/side to side method, will re-establish permeability by removing the metal that is crushed over the pores. Stoning and polishing, up to about a number 800 - 1000 stone/paper finish, is possible. During the stoning and polishing process, it is important to occasionally flush the pores at the surface to prevent packing the pores with debris.

Electric Discharge Machining is the best way to re-establish permeability. This method will burn away the metal fragments that are crushed over the pores by milling and/or grinding.

Note: When using wire EDM machining methods, Porcerax II is porous and generates

waste particles that can create "arcing" conditions between the wire and the work-piece.

This arcing can cut the wire. As a countermeasure, increase wire winding speed.

Note: When using an electrode for EDM, it is important to program a peak-to-valley burn rate that exceeds the pore size; i.e. < 7 micron depth for 7 micron pore size is desirable.

The illustrations above show how particles created by the wire EDM process carry the

electrical current across to the work-piece, creating the potential for a discharge that can break the wire. Increasing the wire winding speed not only greatly reduces the potential for wire breakage but also increases machining times.

本文出自*港峰公司*,转载请注明出处!

模具钢材

模具钢材 铜铝合金

铜铝合金 五金耗材

五金耗材

锣磨加工

锣磨加工 名佳利*葛利兹精品推荐

名佳利*葛利兹精品推荐