设计porcerax II排气钢时,应考虑以下准则:

1.使用的树脂

根据成型过程中的气体排放量或残留评估使用7或20微米孔径。如7微米小气孔新东透气钢,在ABS、聚丙烯树脂、软型聚氯乙烯、聚乙烯、聚丙烯、聚氨酯、苯乙烯中表现良好,对于低粘度或滑石粉填充树脂,它可能需要有一个自动化的系统反向气流互射清除毛孔后的杂质,硬质PVC树脂也适用,但随着被气体长期腐蚀,透气孔会堵塞,如果工件不需要重复利用,这仍然是一个可行方案。

在排气量非常多时,建议采用20微米孔径的新东新东透气钢。20微米怄气刚的开发是为了满足研磨后直接使用,经过正确的研磨,20微米新东透气钢留下的气孔是部分开放(约40-50%)。然而,使用20微米孔径的新东透气钢,并保持20微米孔径,通过电火花加工或研磨抛光后,透气性比7微米更好,但是它也将堵塞得更快。

2.排气区域的面积大小

建议核心腔面积至少10%是PORCERAX II新东透气钢,以确保稳定的排气。虽然这并非总是必要的,它是要记住,在模芯和腔区域中的使用面积,带来的较低的背压是重要的。由于较大的表面积,该新东透气钢工件不需要经常清洗薄的PORCERAX新东透气钢透气性能会更好,不过要注意PORCERAXⅡ新东透气钢的机械性能。太薄的透气钢零件可能无法承受注塑压力。

3.表面光洁度要求

由于大多数的新东透气钢都是应用在模芯侧面来解决,如果电火花的光洁度可以接受,排气性能会是最高的。如果有更高的光洁度要求,研磨抛光的表面将提供一个最好的排气表面。重要的是,如果新东透气钢在模具的模腔侧使用,光泽度就会受到严重降低(#9到#2-3与PP),所以需要考虑是否匹配设计要求。

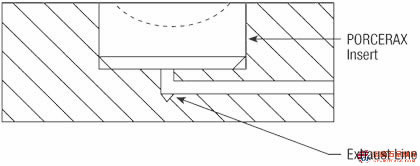

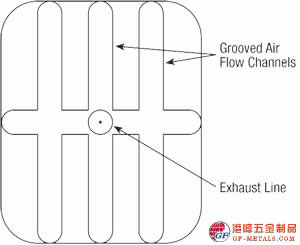

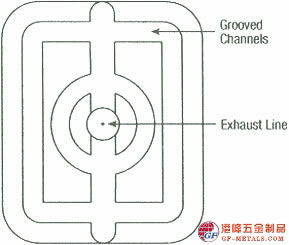

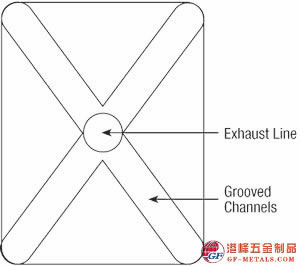

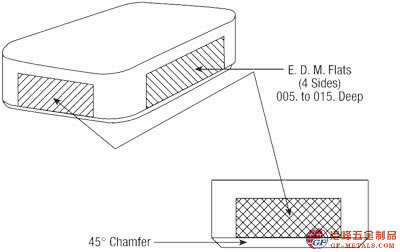

4.透气钢的各种安装槽设计图纸

Porcerax II

Design Guidelines

When designing for Porcerax II venting steel, the following guidelines should be considered:

Resins Used

Depending on the emissions or gas residue given off during the molding process, the molder will have to evaluate whether to use a 7 or 20-micron pore size. Resins such as ABS, polypropylene, soft type PVC, polyethylene, acrylic, polyurethane, and styrene work very well with a 7-micron pore size. For low viscosity or talc-filled resins, it may be necessary to have an automated system reverse the airflow after each shot to purge the impurities from the pores. Rigid PVC resins will work, but only until the corrosive gases close the pores. This can still be a feasible method if disposable inserts are used. Where extreme venting is needed, a 20-micron pore size is recommended. The 20-micron grade was developed to be used with a milled finish. When milled properly this process with the 20-micron material leaves a pore that is partially open (about 40-50 %). However, using the 20-micron pore size material and maintaining the 20-micron pore size, by EDM or polishing after milling, will vent better than 7-micron, but it will also clog faster.

Size of Area to be Vented

The producing mill recommends that at least 10% of the core and cavity area be Porcerax II to insure proper venting. While this is not always possible, it is important to remember that the more square inches used in the core and cavity area, the lower the back pressure will be in the cavity. Due to the larger surface area, the insert will not require cleaning as often as a smaller piece. If Porcerax II is used as a core or cavity half, instead of as an insert, there may not be a need for parting line vents.

Note:The thinner the Porcerax or the shorter the distance air has to travel to the exhaust

line the better the venting will be. Keep in mind the physical properties of Porcerax II.

Note:Porcerax is typically inserted on the core side of the mold in the problem area in

order to hide insert lines.

Surface Finish Requirements

Since most applications can be addressed using inserted pieces on the core side, an EDM finish is acceptable and will vent better than any other surface finish. Should EDM be impractical, a stoned or polished surface will provide the next best venting surface. It is important to remember that if the venting steel is used on the cavity side of a mold, the gloss level will be severely reduced (#9 to a #2-3 with PP), so matching should be considered.

If a low gloss level on a textured part is desired, it can be accomplished with the 7-micron Porcerax II. Certain procedures must be followed to prevent the possible, irreversible damage to the internal pore structure of the material. The texturing house selected for this procedure must be advised that they will be texturing porous, venting steel. The pores must be thoroughly cleaned and sealed prior to texturing. This insures the acid used to etch the surface does not run through the material corroding the interior structure. Performed properly, texturing Porcerax II will give the molder an unmatched finish in terms of definition.

Slide/Lifter Applications

Porcerax II can be used in slide or lifter applications. However, it is important to consider lubrication requirements on such a design. Lubricants will, in all likelihood, reduce or eliminate permeability in areas that come into contact with Porcerax II.

本文出自*港峰公司*,转载请注明出处!

模具钢材

模具钢材 铜铝合金

铜铝合金 五金耗材

五金耗材

锣磨加工

锣磨加工 名佳利*葛利兹精品推荐

名佳利*葛利兹精品推荐